A-A-59959

3.3.6 Fastening devices. All screws, bolts, nuts, pins, and other fastening devices shall be

properly designed, manufactured, and installed with adequate means of preventing loss of torque

or adjustment. Cotter pins, lock washers, or nylon patches shall not be used for this purpose,

except for the attachment of trim items or as provided in commercial components. Tapped

threads shall have a minimum thread engagement in accordance with Table II.

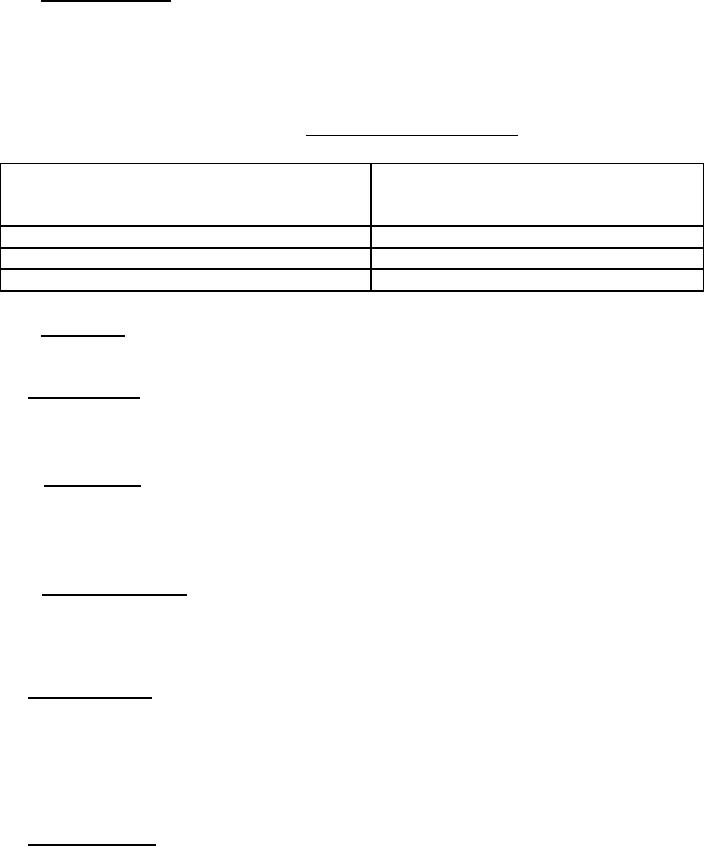

TABLE II. Minimum thread engagement.

Material

Minimum Thread Engagement

Steel

1.0 times the nominal fastener diameter

Cast iron, brass, or bronze

1.5 times the nominal fastener diameter

Aluminum, zinc, or plastic

2.0 times the nominal fastener diameter

3.3.7 Service life. The Mounter and Demounter, Pneumatic Tire, Computer Controlled Torqueing

System shall be designed for a minimum service life of 15 years.

3.4 Maintainability. The Mounter and Demounter, Pneumatic Tire, Computer Controlled

Torqueing System shall be designed for maintainability in accordance with 5.9 through 5.9.18 of

MIL-STD-1472; forces shall not exceed those specified for both males and females.

3.4.1 Special tools. The design of the Mounter and Demounter, Pneumatic Tire, Computer

Controlled Torqueing System shall minimize the requirement for special tools. All special

tools shall be provided with, and stored on, the Mounter and Demounter, Pneumatic Tire,

Computer Controlled Torqueing System.

3.4.2 Diagnostic software. A copy of any diagnostic software required or recommended for

maintaining the Mounter and Demounter, Pneumatic Tire, Computer Controlled Torqueing

System shall be provided with each Mounter and Demounter, Pneumatic Tire, Computer

Controlled Torqueing System on CD-ROM or DVD-ROM.

3.5 Electrical system. The Mounter and Demounter, Pneumatic Tire, Computer Controlled

Torqueing System shall have a 230 volt, negative ground electrical system in accordance with

3.13.1.2 of SAE ARP1247, except as specified herein, single phase, 50/60Hz frequency, 10/20

Amp. If the nut runner/interface has separate circuits, the electrical requirements shall be

compatible with the electrical requirements of the Mounter and Demounter, Pneumatic Tire,

Computer Controlled Torqueing System.

3.6 Hydraulic system. If a hydraulic system is utilized, it shall be in accordance with 3.13.1.3

of SAE ARP1247 except as otherwise specified herein. O-ring face seal hydraulic fittings may

be used in lieu of flared fittings (see 3.13.1.3.12 of SAE ARP1247). Hydraulic fluid shall be in

accordance with MIL-PRF-83282. All hydraulic system components, including the hydraulic

tank, shall comply with all corrosion resistance requirements specified herein. Minimum

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business