A-A-59959

3.2 Mounter and Demounter, Pneumatic Tire, Computer Controlled Torqueing System

description. The Mounter and Demounter, Pneumatic Tire, Computer Controlled Torqueing

System shall provide a simple, safe and reliable means of assembling/disassembling aircraft main

and nose wheels. It shall be designed for efficient operation, with or without the aid of an

overhead hoist, to eliminate heavy lifting by the operator. It shall be designed to provide a stable

horizontal position for wheel bolt torqueing operations. All mechanical operations of the Mounter

and Demounter, Pneumatic Tire, Computer Controlled Torqueing System shall incorporate

emergency stops, for safe operation. The Mounter and Demounter, Pneumatic Tire, Computer

Controlled Torqueing System shall be equipped with a computer controlled twin spindle nut

runner. The nut runner shall be capable of accommodating both odd and even number wheel bolt

patterns. The torqueing system shall have easy to follow instructions to provide the appropriate

torque data for the specific aircraft wheel to be entered. Spindle space settings shall be near

automatic, and not labor intense and time consuming. The Mounter and Demounter, Pneumatic

Tire, Computer Controlled Torqueing System shall be equipped with an operator interface system

which uses a touch screen monitor and an integral Windows operating system. The monitor shall

be mounted to the nut runner positioning fixture and shall be located directly in front of the

operator at a convenient working height when using the torqueing system. The operator interface

system shall identify the specific nut runner spindle spacing for a particular wheel, as well as

other necessary information for assembly and disassembly. The actual final torque values for each

tightening sequence shall be displayed on the operator interface monitor, indicating the pass and

fail criteria. The interface system shall be capable of storing individual wheel torque data for

future reference and report generation. The interface system shall provide menu-driven software

procedures to add or delete wheel data and torque values. Data system must be capable of

password protection.

3.3 Design and construction. The Mounter and Demounter, Pneumatic Tire, Computer

Controlled Torqueing System shall be an electro-hydraulic type. The Mounter and Demounter,

Pneumatic Tire, Computer Controlled Torqueing System shall be designed to be used at depots

and tire shops by personnel of average mechanical skill. The Mounter and Demounter,

Pneumatic Tire, Computer Controlled Torqueing System shall comply with the following

requirements in Table I:

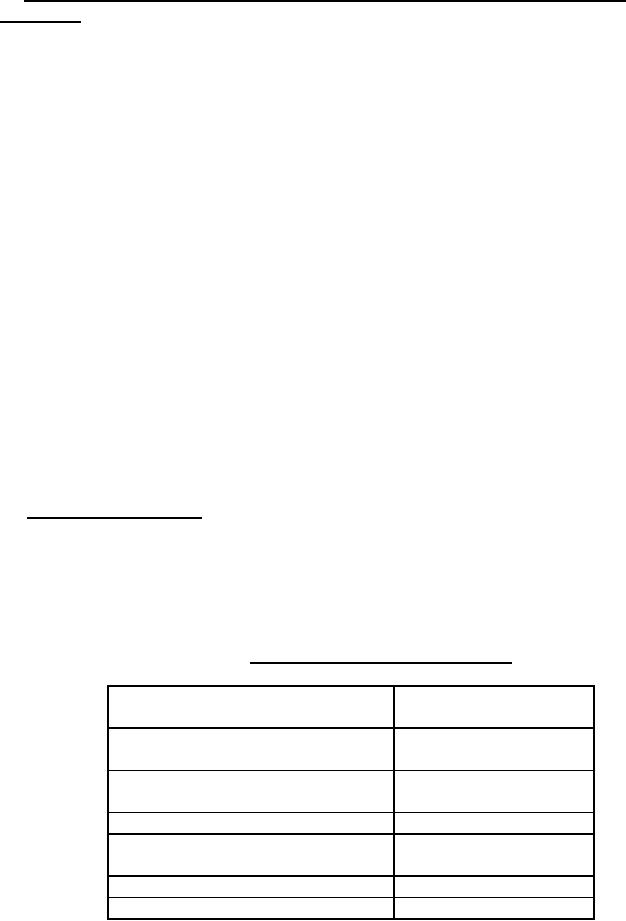

Table I. Design & construction requirements.

Design

Construction

Maximum Overall dimensions

220"W x 140"D x 180"H

(Excluding trolley)

Torque value

80ft-lbs. minimum

370ft-lbs. maximum

Position accessibility around wheel

360 degree

Accommodates aircraft wheels

7" minimum

26" maximum

Bolt tightening accuracy

1% full-scale

Wheel configuration storage capacity 100 minimum

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business